Artistic Pools transforming ordinary Concrete into a work of Art since 1991

Concrete Color Chart from InterStar Click Here!

Slate Patterns

Proline Slate Patterns

Ashlar Slate

Roman Slate

Opa Locka New England Slate

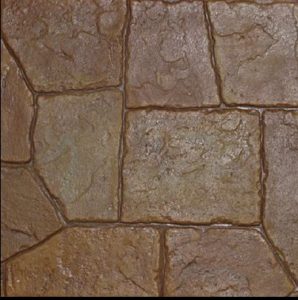

Matcrete Slate Pattern

Ashlar Slate

La Habre Slate

Brickform Slate Pattern

Yorkstone Slate

Ashlar cut Slate

Grand Ashlar Slate

Stone Patterns

Proline Stone Patterns

Random Sandstone

Blue Stone Seamless

Sante Fe Random Stone

Castle Stone

Old Granite Cleft Stone Seamless

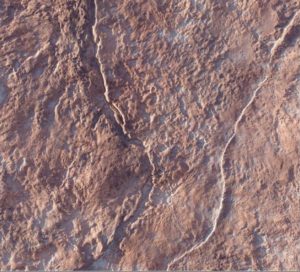

Matcrete Stone Patterns

Random Stone

Cobblestone Patterns

Proline Cobblestone Patterns

Cut Stone Cobble

Appalachian Cobble Stone

European Fan

Matcrete Cobblestone Patterns

Cobblestone

Brick Patterns

Proline Brick Patterns

Used brick runningbond

Used brick basketwave

Matcrete Brick Patterns

New brick herringbone

Wood Patterns

Proline Wood Patterns

12″ Reclaimed Timber

Random Boardwalk

Proline Product brochure

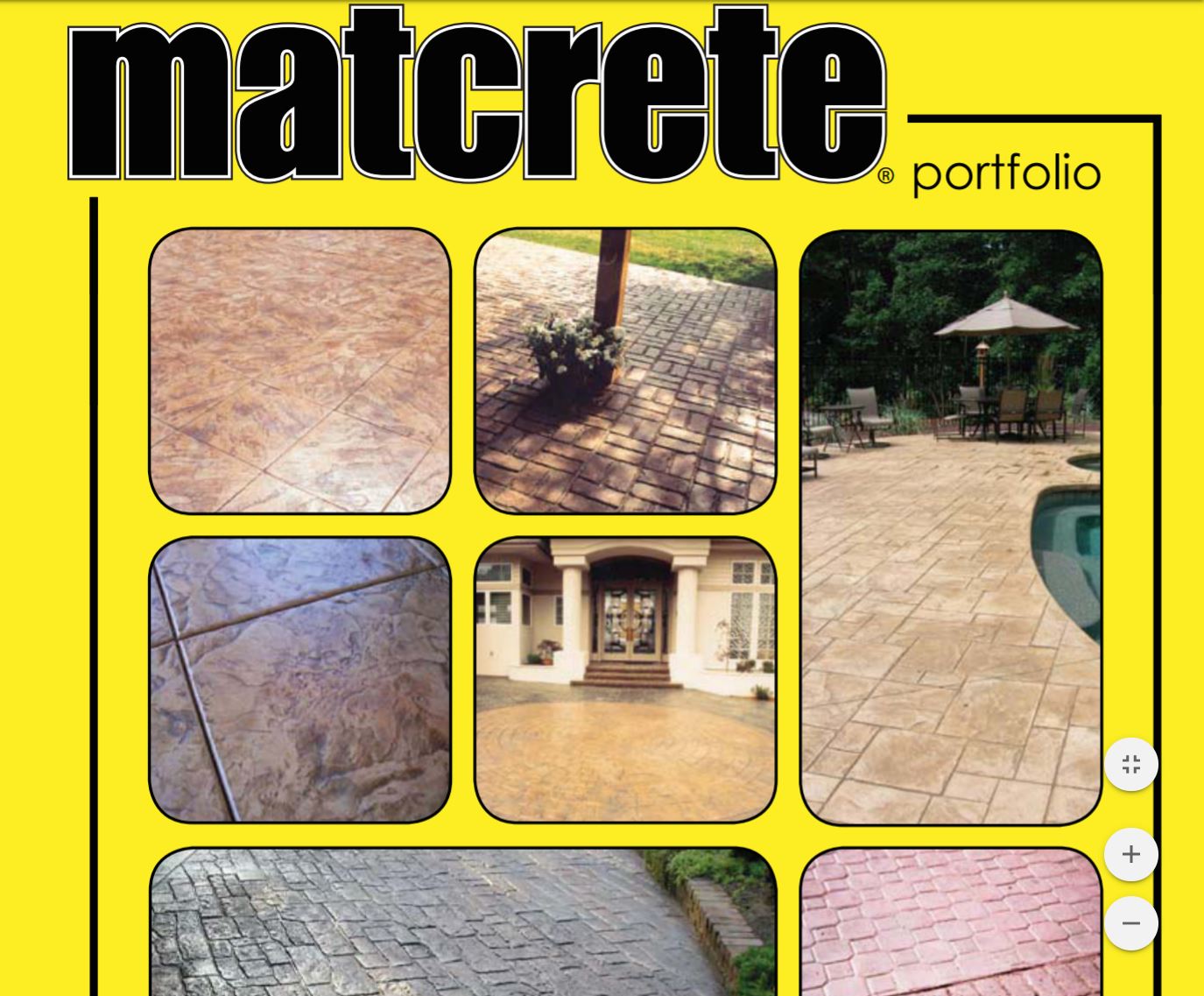

Matcrete Product Brochure

Brickform Product brochure

It seems like not that long ago there was no one installing stamped concrete in new jersey. But in all reality it has been well over thirty years now. My partner and myself both come from a background in masonry. We both helped introduce stamped concrete into new jersey working for a very dear friend of ours Russ Sr. and family. It was then in the late 80’s when most concrete contractors were completely scared and ignorant to this new and upcoming art of concrete. Russ was not scared. For the guys who weren’t scared then, it wound up becoming an extremely lucrative decision. As long as you did good work, the state was yours for the taking. We became so busy that it made good sense to start my own business. I called it Stamped Concrete Specialists. Mark also started his soon after and called it Artistic Concrete Solutions. We then became direct competitors but still remained friends. For many years we did much of the stamped concrete decking for new jersey swimming pool companies whether it was vinyl, gunite, or fiberglass. Throughout those years, we have learned the do’s and dont’s when pouring stamped concrete around swimming pools. Let me share some of my knowledge with you:

Ground preparation

It is critical that the entire area being stamped ESPECIALLY where the walls have been back filled have been tamped properly; otherwise you will see a very long crack running parallel to the coping about 12 inches away after you lift your stamps from the tamping of the stamps. This will happen always if area is left un tamped. Don’t forget.

Concrete mixture

Many may not realize, but this is probably the single most important part of the entire job. Ready mix companies around the state of new jersey and I am sure elsewhere use different admixtures in their concrete. We have found through trial and error what works best for us. It is very simple. First, we take all water reducers out of the concrete. This will ensure to us that when it is time to hand finish the concrete, there will be some water on the surface to help give us the smoothest finish possible. Second, the base or primary color of the job must be put into the concrete truck at the jobsite when it arrives. This eliminates the labor intensive process of broadcasting color after it has been installed. On a hot july day, my workers appreciate that very much.

Installation Process

It is extremely important during the installation you have a strong qualified crew with you. There are just too many things that must be done all at the same time. The crew should also be very efficient with their time. Because as most of us know in the industry, CONCRETE WAITS FOR NO ONE. You are alotted a certain amount of time to work with concrete. That time ranges from 45 minutes up to 3 hours depending on outside temperature. You must remember to still have enough time left over for the stamping process.

Fiberloc Technology by Artistic

Stamping Process

Once again, a strong qualified crew is highly recommended for this stage. One man is needed to broadcast the secondary color across the decking. Two men laying down stamps. One man touching up mistakes with a roller. Two men lifting up stamps already tamped. One man tamping. Having this allows you to do large areas quite efficiently.

Final touch

In the summer, the next day is sufficient for saw cutting all expansion joints and pressure washing the decking clean. At this point, we can highlight other areas with special coloring such as the border or individual stones to give uniqueness to a job.

Seal Coating

We usually wait a day after pressure washing for the area to be completely dry. Using an airless sprayer is the way to go. This allows the sealer to be absorbed and become ONE with the concrete. A big don’t is using a roller. Rolling on the sealer may look good initially, but you are asking for trouble. The laminate becomes to thick on the surface in turn causing delamination. In many cases, taking some of the surface away with it.

In closing, artistic pools corp is very seasoned when it comes to stamped concrete. There isn’t a job we haven’t seen or done. If there are any questions I can help with, please post them and I will be sure to answer all question relating to the Stamped concrete Industry. To view additional posts on the Stamped Concrete industry please visit our blog or click the links to learn more:

To Learn more about the Stamped Concrete Industry you might want to look into:

See Cantilever Coping being installed

See Also Appalachian Cobble Stone

See Also Regular Brushed Concrete

Concrete Color Chart by Solomon Colors

9 thoughts on “Stamped Concrete”

Artistic pools can indeed transform ordinary concrete into stunning works of art.

Artistic Pools Corp in New Jersey sets a new standard for luxury outdoor living through innovative stamped concrete designs that elevate ordinary spaces into extraordinary works of art.

If the place were not as perfect as this view this pool looks nothing but with the city view the area looks beautiful and perfect with its designs.

what is it about beautiful stone work that is so satisfying, love that random sandstone.

Totally agree. Stonework is just so satisfying…

yes I agree with you, a strong qualified crew is highly recommended for stamping stage One man is always needed to broadcast the secondary color across the decking

nice post

Nice blog. It helps that you are the one who first established the concrete sealing in New Jersey. You are brave enough and your idea opens the door in concrete industry. I love how you give details about the concreting process of stamping.

I am glad that you mentioned that you apply the techniques that ready-mix companies from new jersey use in their job. I like how you eliminate the additional funds of hiring them to save costs. If I were to make a Ready Mix Cement Supplier, Services, I will collaborate with a pool making company that can help me a lot.